Main features:

The material in contact with the material is 304 stainless steel;

Touch screen operation, convenient and simple, stable performance;

Automatic alarm for wrong operation, safe and reliable;

High quality pneumatic components;

Technical parameter:

Voltage: 220V/50Hz

Power: 1.2kw

Loading range: 10~20 pieces/bottle

Diameter: 16~30MM

Thickness: 3~8MM

Output: 30 bottles/min

Purified compressed air: 0.5~0.7MPa

Dosage: 0.28M

Size: 1800*1600*1600

Weight: 420KG

The above parameters can be produced according to user requirements.

Composition and function:

Feed film into bottle part:

Manually put the tablets into the tablet storage bucket, through the filter hole, remove the irregular tablets, and remove the excess powder on the tablets, and then automatically arrange into the number of tablets that need to be loaded. Automatic rolling and discharge to each track, in the process of automatic rolling and discharge, multiple filtration, and finally the excess dust is discharged through the pipeline. Automatically send the tablet to the loading position. When a bottle is detected at the loading position, the feeding cylinder automatically sends the tablet into the bottle.

Bottle, bottle pouring part: manually put the bottle into the bottle bucket in the same direction, the machine will automatically arrange the bottles into the loading position, after reaching the pouring position, erect the medicine bottle, waiting for the tablet pouring.

Feeding the cover oscillating disc: Manually put the cover into the oscillating disc, and the oscillation will automatically send the cover to the fixed gland position in the set direction.

Capping, bottle out part: When the bottle is detected and contains tablets, the capping part will automatically press the cap into the bottle opening. No pieces, less pieces do not cap, and automatically remove the bottle without cap to ensure that the final bottle meets the preset standard.

Electronic control part: The whole operation process of the equipment is controlled by PLC and automatically executed in order. When a package is missing, it will automatically alarm and delay the shutdown. PLC and touch screen using Siemens intelligent control, to achieve the entire line of automatic production. The operating system is simple and clear, the interface is clear, the data changes can be observed from the interface, and the dynamics can be grasped at any time.

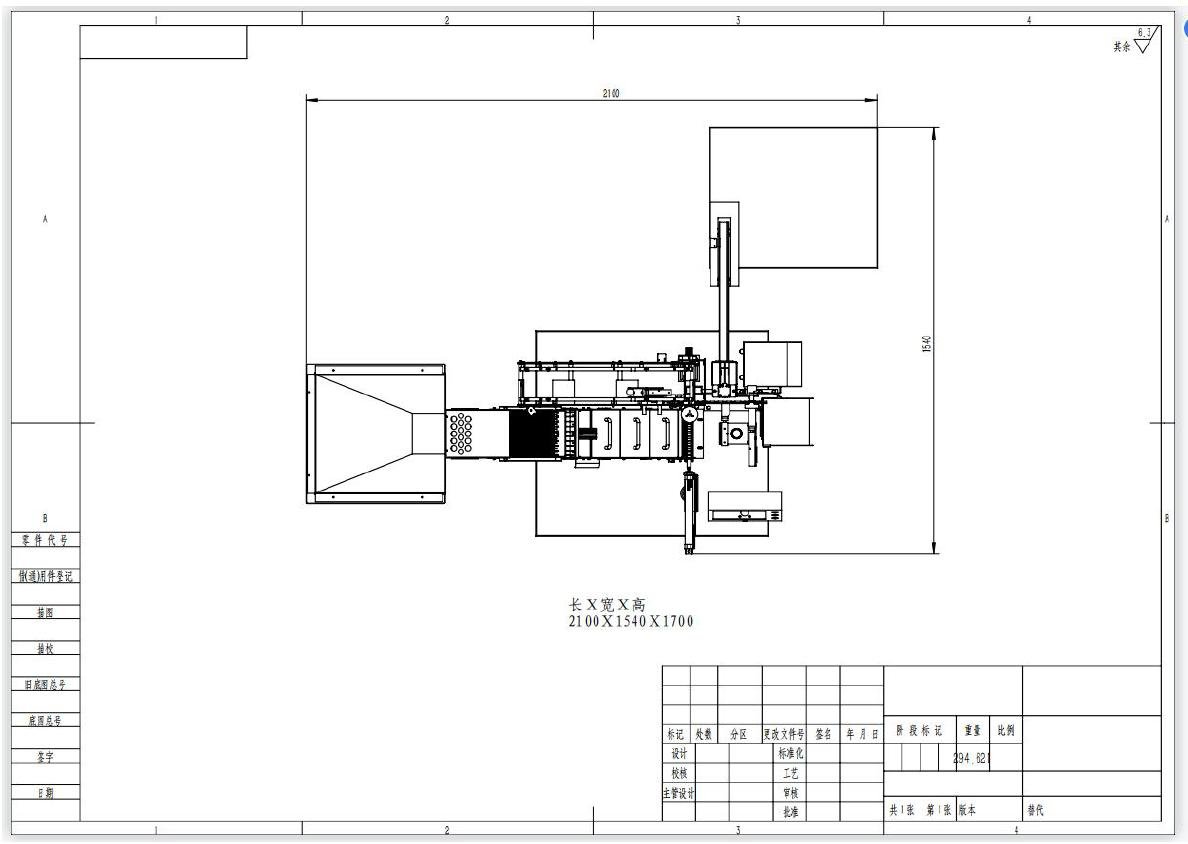

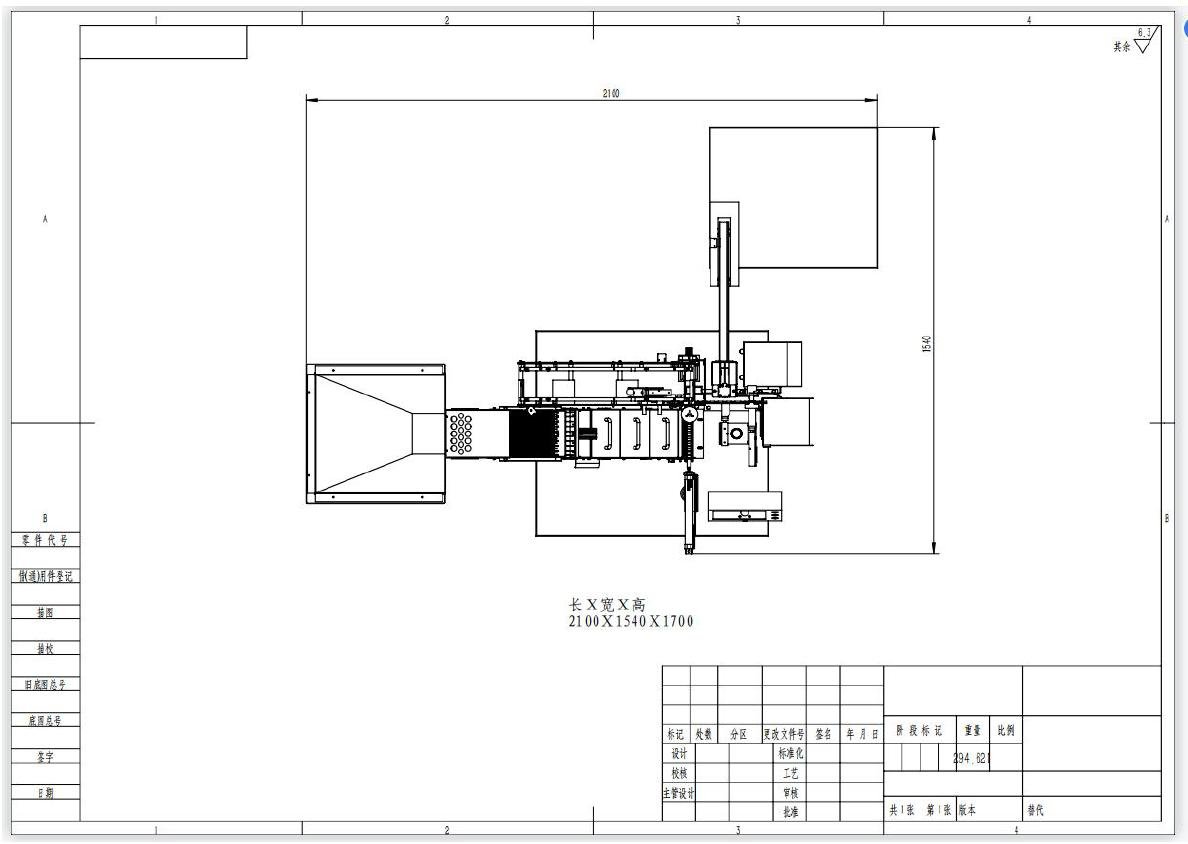

Equipment plane diagram (top view)